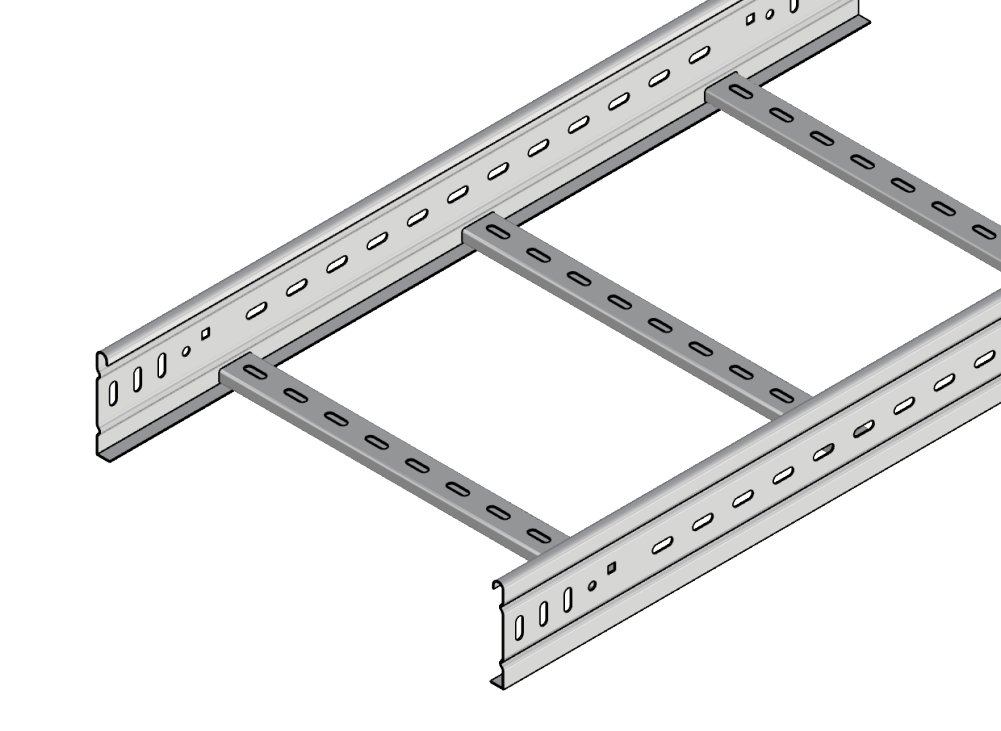

Cable Ladder

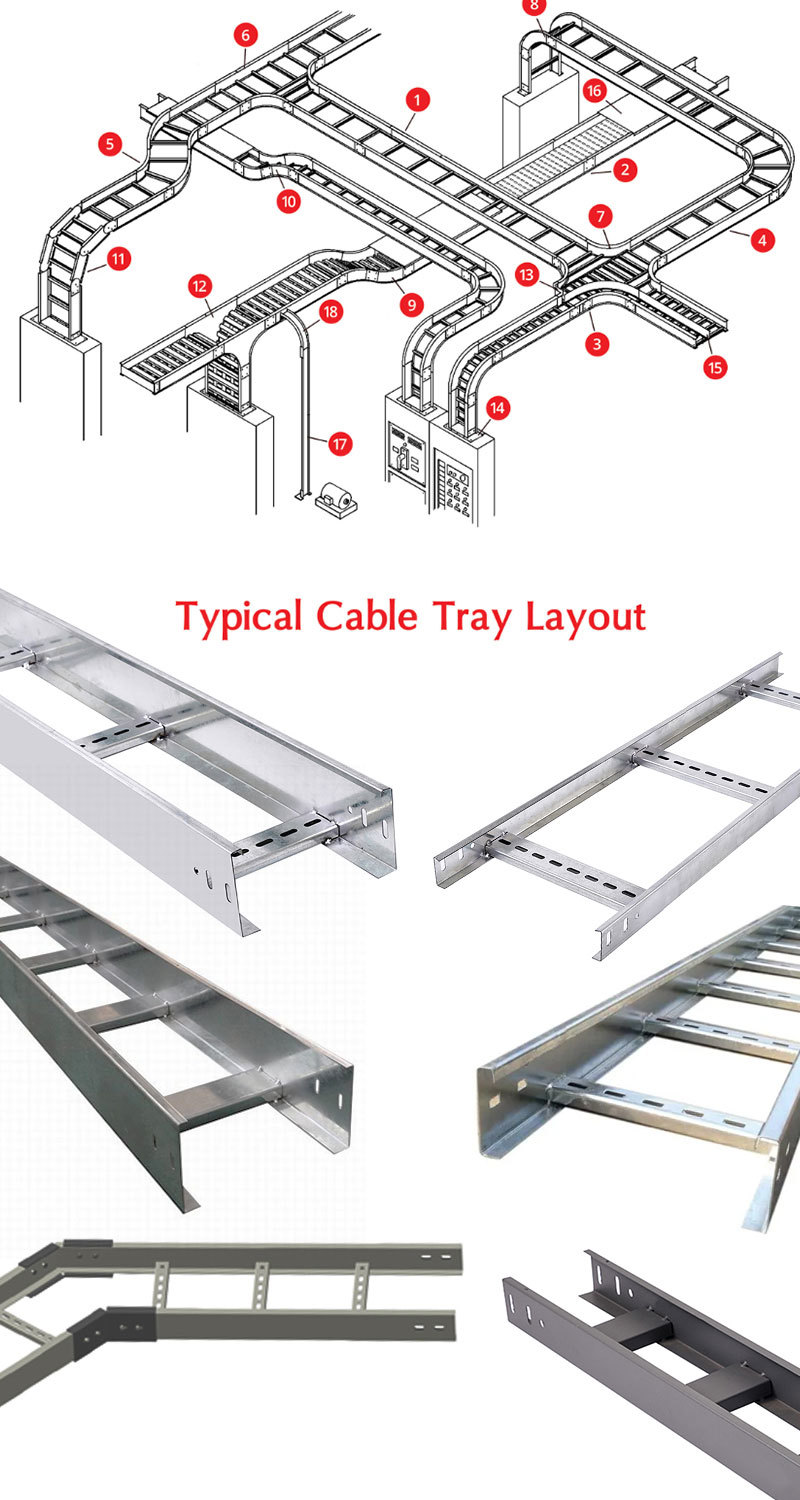

Main products: wire mesh cable trays, cable trays, cable ducts, cable ladders, wire ducts, pillar channels and accessories.

Keywords:

Cable Ladder

Category:

Description

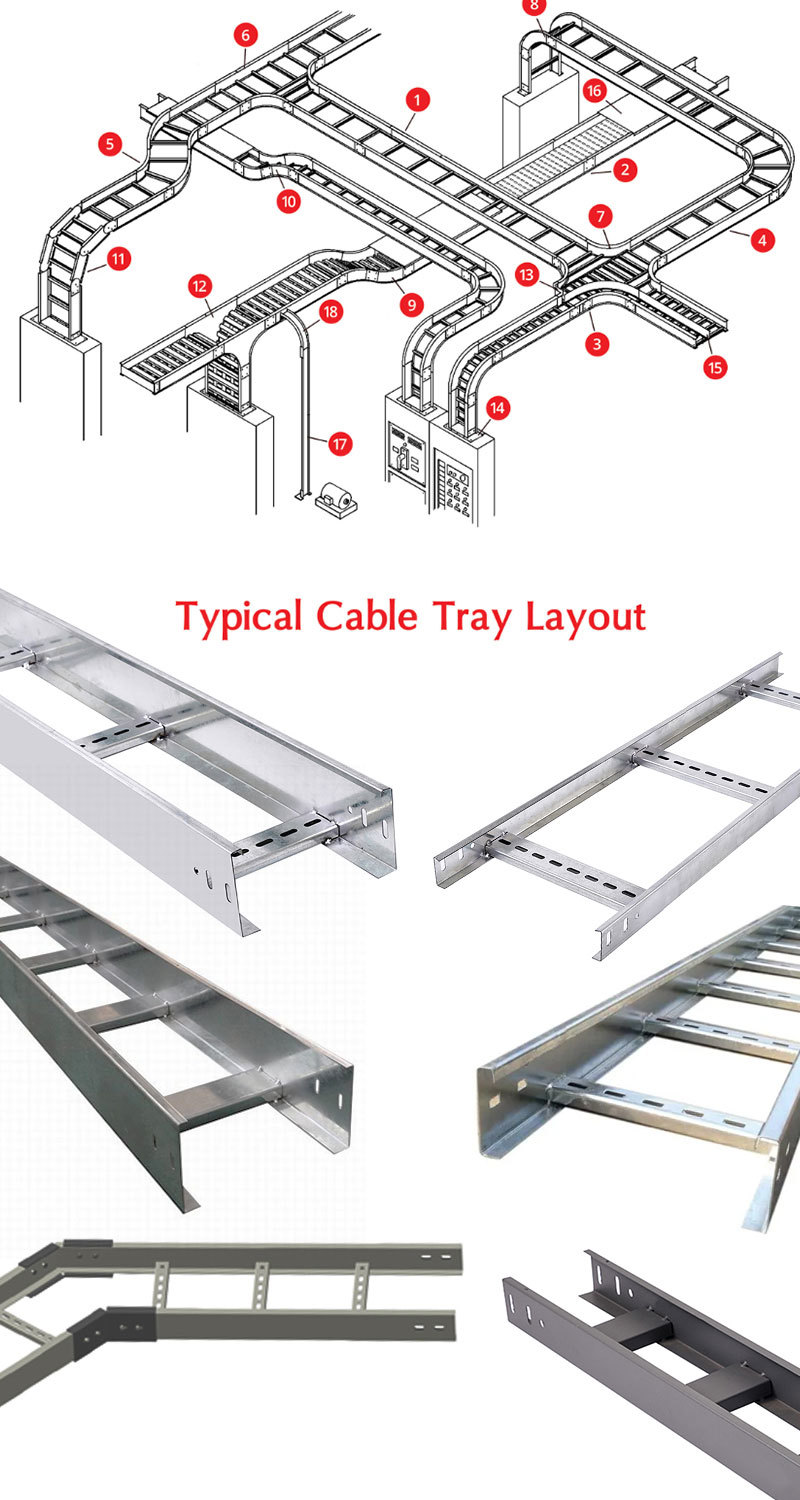

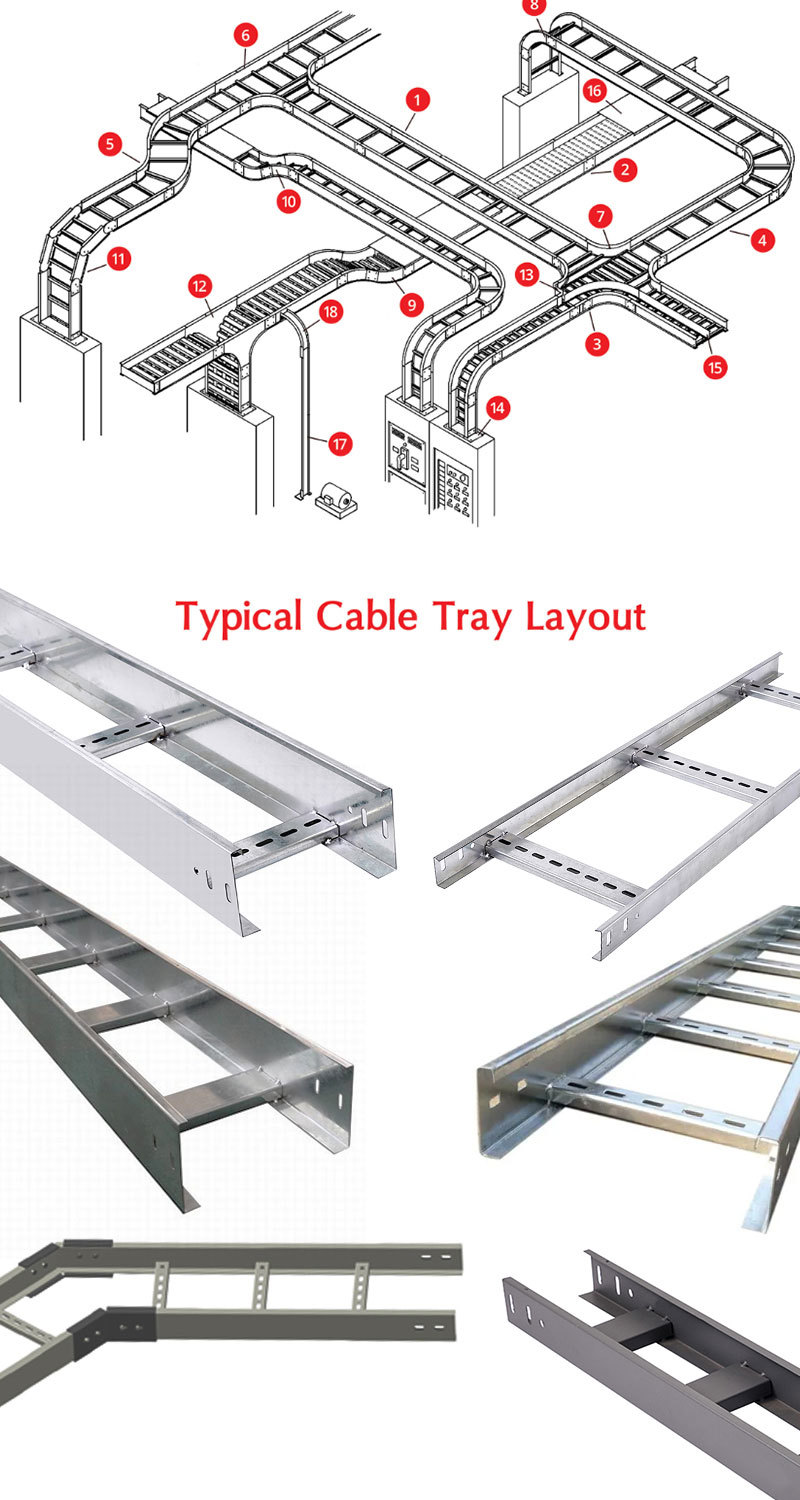

| Product type | Cable Ladder | |

| Material | Mild Steel(Q235) | |

| Surface Treatment | Hot dipped galvanized(45um,65um,85um) | |

| Size | Width | 50-1200mm |

| Side rail height | 25-300mm | |

| Length | 22000-9000mm or Customization | |

| Thickness | 0.6-3mm | |

| Steel Thickness (Recommend) |

1.00mm- Width:50~100mm | |

| 1.2mm-Width:100mm~150mm | ||

| 1.5mm-Width:150mm~350mm | ||

| 2.0mm-Width:450mm~700mm | ||

| 2.5mm-800*1200mm | ||

| As customer requirements | ||

| Color | As customer requirements | |

| Certification | ISO9001/IEC61537/CE | |

| Used | Wiring system,cable management,hoisting system,construction industry and so on | |

| Loading Test | Comply with the standards requirements of IEC61537 and ISO9001 | |

| Non standard specifications are availabe according to customers'requirement | ||

Hot-Dip Galvanized Ladder Cable Tray: Advantages and Applications

I. Advantages of Hot-Dip Galvanized Ladder Cable Trays

(1) Superior Anti-Corrosion Performance

The hot-dip galvanizing process involves immersing ladder trays in high-temperature molten zinc, creating a composite coating consisting of zinc-iron alloy layers and pure zinc layers on the tray surface. This coating reaches a thickness of 55μm - 86μm, providing dense coverage with strong adhesion that effectively isolates the tray from air, moisture, and corrosive media, successfully resisting various corrosive factors. Whether in humid, rainy southern regions or polluted environments with industrial waste gases and wastewater, hot-dip galvanized ladder cable trays maintain structural integrity for extended periods. With a service life of 20-30 years, they significantly reduce replacement frequency and costs associated with corrosion damage.

(2) Excellent Ventilation and Heat Dissipation

The unique ladder-like structure allows air to circulate freely within the tray, providing exceptional ventilation and breathability. When cables generate heat during operation, hot-dip galvanized ladder cable trays quickly dissipate this heat, preventing temperature buildup that could affect cable performance and lifespan. This characteristic makes them excel in scenarios requiring long-term, high-load cable operation, effectively ensuring power transmission stability.

(3) Convenient Large-Diameter Cable Installation and Maintenance

Hot-dip galvanized ladder cable trays offer spacious interiors that are extremely accommodating for large-diameter cable installation. Construction personnel can easily lay cables on the trays and perform securing operations without complex bending and pulling processes, significantly improving construction efficiency. During maintenance, cables remain fully exposed and clearly visible, allowing workers to quickly locate fault points for repair and replacement, reducing maintenance difficulty and time costs.

(4) High Strength and Load-Bearing Capacity

Manufactured from steel and treated with hot-dip galvanizing, ladder cable trays retain steel's inherent high-strength characteristics, providing strong load-bearing capacity capable of supporting heavy cable installations. In projects requiring numerous power cables, hot-dip galvanized ladder cable trays can stably support cable weight without deformation or breakage issues, ensuring cable installation safety.

(5) Convenient Installation and Economic Cost

Hot-dip galvanized ladder cable trays feature simple structures and relatively light weight, requiring lower labor and material costs during installation. Their modular design allows flexible combination and adjustment according to actual project requirements, adapting to various installation environments. While hot-dip galvanizing adds certain costs, compared to frequent replacement of corrosion-damaged trays, hot-dip galvanized ladder cable trays offer superior cost-effectiveness from a long-term perspective.

II. Application Scenarios for Hot-Dip Galvanized Ladder Cable Trays

(1) Factories and Mines

In factory workshops, particularly in mechanical manufacturing, metallurgy, and chemical industries, numerous production equipment requiring power supply creates demand for multiple large-diameter cables. Hot-dip galvanized ladder cable trays, with their excellent load-bearing capacity and ventilation heat dissipation properties, meet large-diameter power cable installation requirements. Their superior anti-corrosion performance resists erosion from metallic dust, oil contamination, and corrosive gases within workshops. In mining operations, whether in underground tunnels or surface mining areas with humid, dark environments containing dust and ore debris, hot-dip galvanized ladder cable trays effectively prevent tray rust and cable damage, ensuring stable mining power system operation.

(2) Substations and Power Plants

Substations and power plants feature dense cable concentrations with high power transmission loads, demanding extremely high load-bearing capacity, heat dissipation performance, and stability from cable trays. Hot-dip galvanized ladder cable trays can support numerous high-voltage, high-current cables, with excellent ventilation facilitating cable heat dissipation and reducing overheating safety hazards. Additionally, hot-dip galvanizing's anti-corrosion characteristics enable performance maintenance in complex outdoor environments with prolonged exposure to sunlight, rain, and wind-blown sand, ensuring normal power equipment operation.

(3) Large Commercial Buildings and Transportation Hubs

In large commercial buildings such as shopping malls and centers, as well as transportation hubs like train stations and airports, complex electrical systems require extensive cable networks. Hot-dip galvanized ladder cable trays facilitate centralized cable installation and management, with open structures convenient for future cable additions, removals, and adjustments to accommodate changing power demands and equipment upgrades in commercial venues and transportation hubs. Simultaneously, hot-dip galvanizing's anti-corrosion performance addresses potential impacts from humid air and cleaning agent vapors in high-traffic areas.

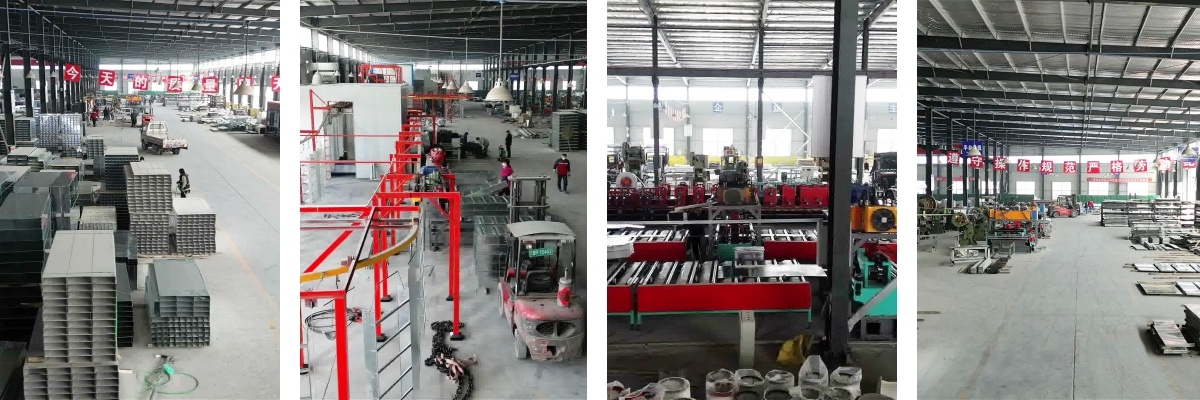

Our company and our team

Workshop and production line

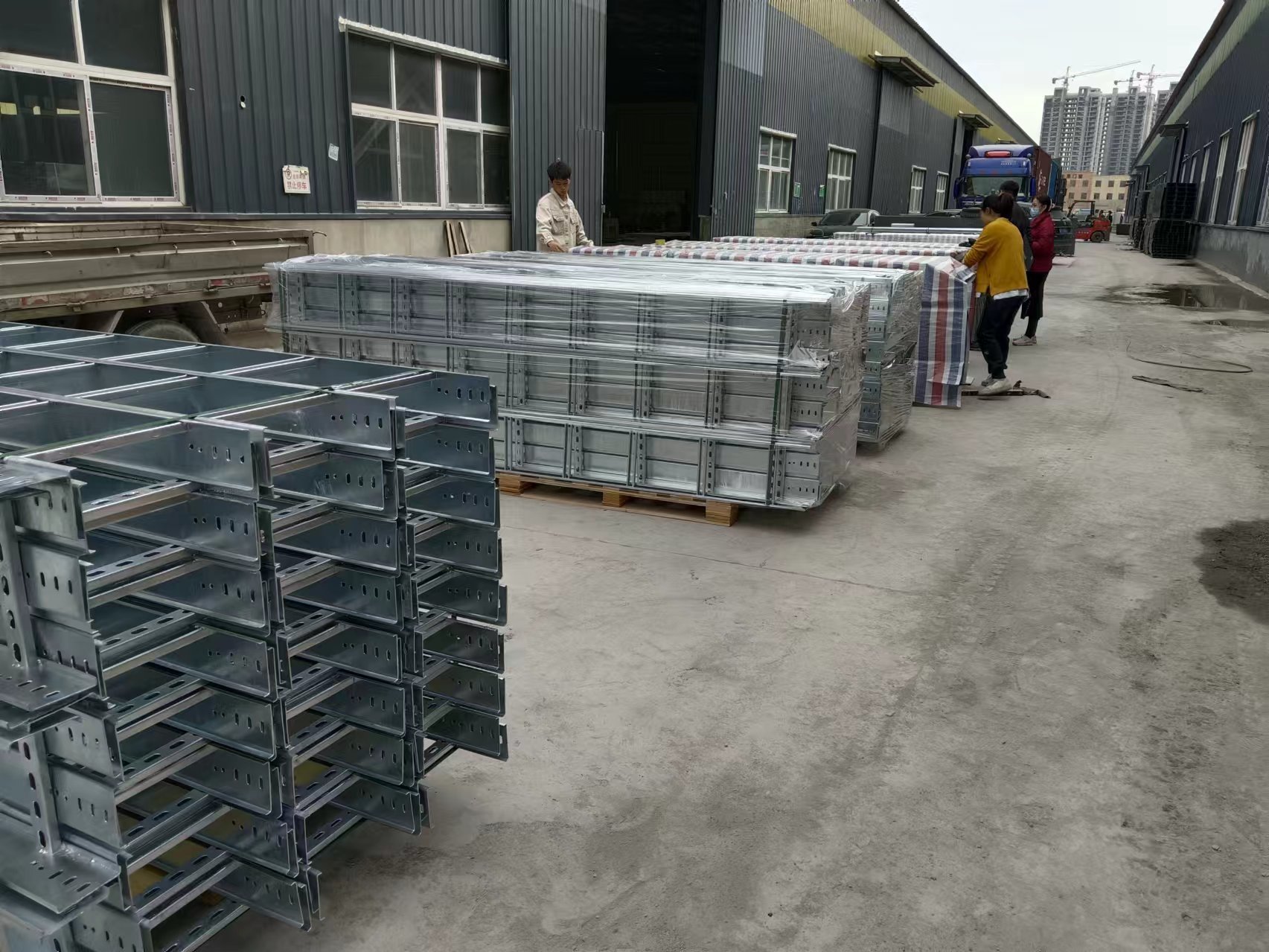

Warehouse delivery

Welcome to consult us

Cable Ladder

| Product type | Cable Ladder | |

| Material | Mild Steel(Q235) | |

| Surface Treatment | Hot dipped galvanized(45um,65um,85um) | |

| Size | Width | 50-1200mm |

| Side rail height | 25-300mm | |

| Length | 22000-9000mm or Customization | |

| Thickness | 0.6-3mm | |

| Steel Thickness (Recommend) |

1.00mm- Width:50~100mm | |

| 1.2mm-Width:100mm~150mm | ||

| 1.5mm-Width:150mm~350mm | ||

| 2.0mm-Width:450mm~700mm | ||

| 2.5mm-800*1200mm | ||

| As customer requirements | ||

| Color | As customer requirements | |

| Certification | ISO9001/IEC61537/CE | |

| Used | Wiring system,cable management,hoisting system,construction industry and so on | |

| Loading Test | Comply with the standards requirements of IEC61537 and ISO9001 | |

| Non standard specifications are availabe according to customers'requirement | ||

Hot-Dip Galvanized Ladder Cable Tray: Advantages and Applications

I. Advantages of Hot-Dip Galvanized Ladder Cable Trays

(1) Superior Anti-Corrosion Performance

The hot-dip galvanizing process involves immersing ladder trays in high-temperature molten zinc, creating a composite coating consisting of zinc-iron alloy layers and pure zinc layers on the tray surface. This coating reaches a thickness of 55μm - 86μm, providing dense coverage with strong adhesion that effectively isolates the tray from air, moisture, and corrosive media, successfully resisting various corrosive factors. Whether in humid, rainy southern regions or polluted environments with industrial waste gases and wastewater, hot-dip galvanized ladder cable trays maintain structural integrity for extended periods. With a service life of 20-30 years, they significantly reduce replacement frequency and costs associated with corrosion damage.

(2) Excellent Ventilation and Heat Dissipation

The unique ladder-like structure allows air to circulate freely within the tray, providing exceptional ventilation and breathability. When cables generate heat during operation, hot-dip galvanized ladder cable trays quickly dissipate this heat, preventing temperature buildup that could affect cable performance and lifespan. This characteristic makes them excel in scenarios requiring long-term, high-load cable operation, effectively ensuring power transmission stability.

(3) Convenient Large-Diameter Cable Installation and Maintenance

Hot-dip galvanized ladder cable trays offer spacious interiors that are extremely accommodating for large-diameter cable installation. Construction personnel can easily lay cables on the trays and perform securing operations without complex bending and pulling processes, significantly improving construction efficiency. During maintenance, cables remain fully exposed and clearly visible, allowing workers to quickly locate fault points for repair and replacement, reducing maintenance difficulty and time costs.

(4) High Strength and Load-Bearing Capacity

Manufactured from steel and treated with hot-dip galvanizing, ladder cable trays retain steel's inherent high-strength characteristics, providing strong load-bearing capacity capable of supporting heavy cable installations. In projects requiring numerous power cables, hot-dip galvanized ladder cable trays can stably support cable weight without deformation or breakage issues, ensuring cable installation safety.

(5) Convenient Installation and Economic Cost

Hot-dip galvanized ladder cable trays feature simple structures and relatively light weight, requiring lower labor and material costs during installation. Their modular design allows flexible combination and adjustment according to actual project requirements, adapting to various installation environments. While hot-dip galvanizing adds certain costs, compared to frequent replacement of corrosion-damaged trays, hot-dip galvanized ladder cable trays offer superior cost-effectiveness from a long-term perspective.

II. Application Scenarios for Hot-Dip Galvanized Ladder Cable Trays

(1) Factories and Mines

In factory workshops, particularly in mechanical manufacturing, metallurgy, and chemical industries, numerous production equipment requiring power supply creates demand for multiple large-diameter cables. Hot-dip galvanized ladder cable trays, with their excellent load-bearing capacity and ventilation heat dissipation properties, meet large-diameter power cable installation requirements. Their superior anti-corrosion performance resists erosion from metallic dust, oil contamination, and corrosive gases within workshops. In mining operations, whether in underground tunnels or surface mining areas with humid, dark environments containing dust and ore debris, hot-dip galvanized ladder cable trays effectively prevent tray rust and cable damage, ensuring stable mining power system operation.

(2) Substations and Power Plants

Substations and power plants feature dense cable concentrations with high power transmission loads, demanding extremely high load-bearing capacity, heat dissipation performance, and stability from cable trays. Hot-dip galvanized ladder cable trays can support numerous high-voltage, high-current cables, with excellent ventilation facilitating cable heat dissipation and reducing overheating safety hazards. Additionally, hot-dip galvanizing's anti-corrosion characteristics enable performance maintenance in complex outdoor environments with prolonged exposure to sunlight, rain, and wind-blown sand, ensuring normal power equipment operation.

(3) Large Commercial Buildings and Transportation Hubs

In large commercial buildings such as shopping malls and centers, as well as transportation hubs like train stations and airports, complex electrical systems require extensive cable networks. Hot-dip galvanized ladder cable trays facilitate centralized cable installation and management, with open structures convenient for future cable additions, removals, and adjustments to accommodate changing power demands and equipment upgrades in commercial venues and transportation hubs. Simultaneously, hot-dip galvanizing's anti-corrosion performance addresses potential impacts from humid air and cleaning agent vapors in high-traffic areas.

Our company and our team

Workshop and production line

Warehouse delivery

Welcome to consult us

- 产品描述

-

- Commodity name: Cable Ladder

Product type Cable Ladder Material Mild Steel(Q235) Surface Treatment Hot dipped galvanized(45um,65um,85um) Size Width 50-1200mm Side rail height 25-300mm Length 22000-9000mm or Customization Thickness 0.6-3mm Steel Thickness

(Recommend)1.00mm- Width:50~100mm 1.2mm-Width:100mm~150mm 1.5mm-Width:150mm~350mm 2.0mm-Width:450mm~700mm 2.5mm-800*1200mm As customer requirements Color As customer requirements Certification ISO9001/IEC61537/CE Used Wiring system,cable management,hoisting system,construction industry and so on Loading Test Comply with the standards requirements of IEC61537 and ISO9001 Non standard specifications are availabe according to customers'requirement

Hot-Dip Galvanized Ladder Cable Tray: Advantages and Applications

I. Advantages of Hot-Dip Galvanized Ladder Cable Trays

(1) Superior Anti-Corrosion Performance

The hot-dip galvanizing process involves immersing ladder trays in high-temperature molten zinc, creating a composite coating consisting of zinc-iron alloy layers and pure zinc layers on the tray surface. This coating reaches a thickness of 55μm - 86μm, providing dense coverage with strong adhesion that effectively isolates the tray from air, moisture, and corrosive media, successfully resisting various corrosive factors. Whether in humid, rainy southern regions or polluted environments with industrial waste gases and wastewater, hot-dip galvanized ladder cable trays maintain structural integrity for extended periods. With a service life of 20-30 years, they significantly reduce replacement frequency and costs associated with corrosion damage.

(2) Excellent Ventilation and Heat Dissipation

The unique ladder-like structure allows air to circulate freely within the tray, providing exceptional ventilation and breathability. When cables generate heat during operation, hot-dip galvanized ladder cable trays quickly dissipate this heat, preventing temperature buildup that could affect cable performance and lifespan. This characteristic makes them excel in scenarios requiring long-term, high-load cable operation, effectively ensuring power transmission stability.

(3) Convenient Large-Diameter Cable Installation and Maintenance

Hot-dip galvanized ladder cable trays offer spacious interiors that are extremely accommodating for large-diameter cable installation. Construction personnel can easily lay cables on the trays and perform securing operations without complex bending and pulling processes, significantly improving construction efficiency. During maintenance, cables remain fully exposed and clearly visible, allowing workers to quickly locate fault points for repair and replacement, reducing maintenance difficulty and time costs.

(4) High Strength and Load-Bearing Capacity

Manufactured from steel and treated with hot-dip galvanizing, ladder cable trays retain steel's inherent high-strength characteristics, providing strong load-bearing capacity capable of supporting heavy cable installations. In projects requiring numerous power cables, hot-dip galvanized ladder cable trays can stably support cable weight without deformation or breakage issues, ensuring cable installation safety.

(5) Convenient Installation and Economic Cost

Hot-dip galvanized ladder cable trays feature simple structures and relatively light weight, requiring lower labor and material costs during installation. Their modular design allows flexible combination and adjustment according to actual project requirements, adapting to various installation environments. While hot-dip galvanizing adds certain costs, compared to frequent replacement of corrosion-damaged trays, hot-dip galvanized ladder cable trays offer superior cost-effectiveness from a long-term perspective.

II. Application Scenarios for Hot-Dip Galvanized Ladder Cable Trays

(1) Factories and Mines

In factory workshops, particularly in mechanical manufacturing, metallurgy, and chemical industries, numerous production equipment requiring power supply creates demand for multiple large-diameter cables. Hot-dip galvanized ladder cable trays, with their excellent load-bearing capacity and ventilation heat dissipation properties, meet large-diameter power cable installation requirements. Their superior anti-corrosion performance resists erosion from metallic dust, oil contamination, and corrosive gases within workshops. In mining operations, whether in underground tunnels or surface mining areas with humid, dark environments containing dust and ore debris, hot-dip galvanized ladder cable trays effectively prevent tray rust and cable damage, ensuring stable mining power system operation.

(2) Substations and Power Plants

Substations and power plants feature dense cable concentrations with high power transmission loads, demanding extremely high load-bearing capacity, heat dissipation performance, and stability from cable trays. Hot-dip galvanized ladder cable trays can support numerous high-voltage, high-current cables, with excellent ventilation facilitating cable heat dissipation and reducing overheating safety hazards. Additionally, hot-dip galvanizing's anti-corrosion characteristics enable performance maintenance in complex outdoor environments with prolonged exposure to sunlight, rain, and wind-blown sand, ensuring normal power equipment operation.

(3) Large Commercial Buildings and Transportation Hubs

In large commercial buildings such as shopping malls and centers, as well as transportation hubs like train stations and airports, complex electrical systems require extensive cable networks. Hot-dip galvanized ladder cable trays facilitate centralized cable installation and management, with open structures convenient for future cable additions, removals, and adjustments to accommodate changing power demands and equipment upgrades in commercial venues and transportation hubs. Simultaneously, hot-dip galvanizing's anti-corrosion performance addresses potential impacts from humid air and cleaning agent vapors in high-traffic areas.

Our company and our team

Workshop and production line

Warehouse delivery

Welcome to consult us

Related Products

Submit information for support

Hongfeng Group has become one of the "best-selling brands" in the cable tray industry with its plant size, product quality and warm service.Sincerely hope to serve our customers with the best service and quality and create value for all customers. We are trying our best to be your most satisfied partner.

No.2 House, Jialong Road, Jiaming Industrial Park, Dongchangfu District, Liaocheng City, Shandong Province, China